101 Series: Stranded vs. Solid Patch Cords

August 21, 2019 / General, 101 learning, Installation and testing, Best Practices

You’ve likely heard copper patch cords referred to as being constructed of either “stranded” or “solid” cable, but do you know the difference and which to choose when?

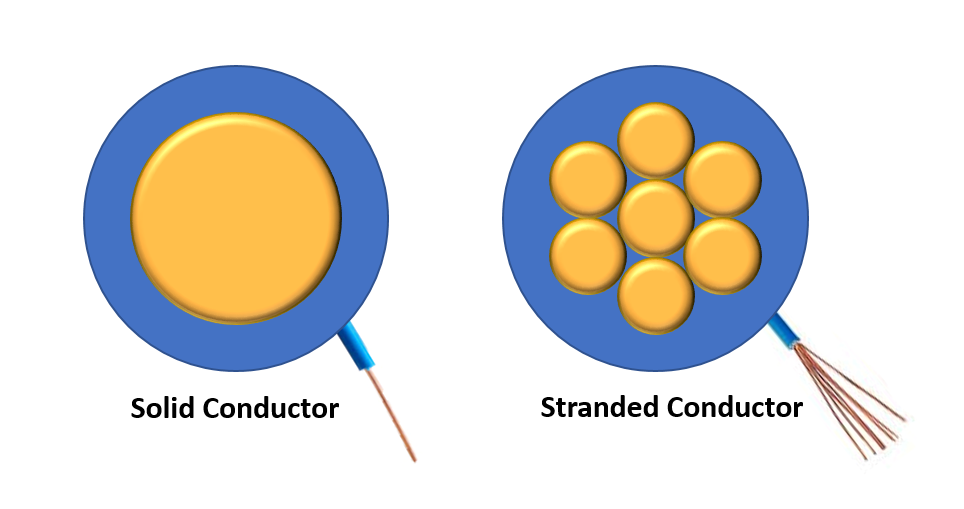

Just like the name implies, stranded four-pair cables are cables where each of the eight conductors of the four-pair cable are constructed of multiple “strands” of wires wrapped around each other, while solid cables are constructed with just one solid copper wire per conductor.

In a stranded cable, the wires that form the conductor are typically very thin wires that are wound concentrically in a helix to form the conductor (think of this like a rope). The construction of stranded cable is specified as two numbers – the number of strands as the first number and the gauge of the strand as the second number. For example, a 7X32 (sometimes written as 7/32) indicates that there are 7 strands of 32 AWG wire that make up the conductor. In contrast, solid cable will just include one gauge number to indicate the size of the conductor.

But aren’t stranded and solid cables of the same category type the same gauge size? Yes, indeed they are. That’s because the final conductor size, regardless of whether it is made up of multiple strands or one solid conductor, are the same. In other words, a 24 AWG cable is still a 24 AWG cable.

How Do they Differ?

The key physical difference between a stranded cable and a solid cable is flexibility. Stranded cables are much more flexible and can withstand more bending compare to rigid solid conductors that can fail if flexed too many times. And the more strands a conductor has, the greater the flexibility. Strand count can also impact cost – the more strands that make up a wire, the greater the cost. To keep costs down, stranded twisted-pair cable uses a high enough strand count to maintain proper flexibility but not so many that it creates a dramatic price difference. In other words, it’s a careful balance between cost and flexibility.

The construction of the cable also impacts termination. IDCs on jacks, patch panels and connecting blocks are made for solid cable. The individual conductors of a solid cable will hold their shape and properly seat in the IDC, while stranded conductors will typically break and can come loose over time. Solid wire is also considered more rugged and less susceptible to corrosion since it has less surface area than a stranded wire.

Another key difference is electrical performance. Solid cables are better electrical conductors and provide superior, stable electrical characteristics over a wider range of frequencies, offering lower susceptibility to high-frequency effects and lower DC resistance than stranded cables. That’s precisely why TIA standards allow a 20% increase in attenuation for stranded construction.

Which do I Choose?

When it comes to horizontal cable runs, there is no choice. Solid cable is the standard due to its better electrical performance and ability to punch down to IDCs . Where you do have a choice is with patch cords since most manufacturers offer both.

Because stranded cables are more flexible and can withstand bending, they make excellent patch cords for equipment connections and cross-connects where cables are frequently bent and manipulated. Patch cords are also shorter in length, so the higher resistance of the stranded construction is not typically a concern.

There is however a primary application in today’s LANs that warrants the use of solid patch cords – power over Ethernet. When PoE is delivered over twisted-pair copper cabling, some of the power dissipates as heat. When power dissipates as heat, the temperature within the cable can increase. With their higher DC resistance, stranded patch cords are more likely to exhibit degraded transmission performance at elevated temperatures.

While not typically a concern in environmentally-controlled spaces like the TR, once you start connecting devices in the ceiling (think wireless access points, security cameras and LED lights), stranded patch cords could be an issue. A good rule of thumb is that if the environment is not temperature controlled and there’s not a lot of manipulation going on, choose a solid patch cord. If you do use stranded patch cords in uncontrolled environments, you’re better off keeping them short (about 5 meters or less). And if you’re skeptical, check it out yourself. Fluke Network’s DSX Series Patch Cord Test Adapters can be used to test copper patch cords or you can see the difference in channel testing.