7 Reasons to Certify

August 13, 2019 / General, 101 learning, Standard and Certification, Upgrading and troubleshooting, Best Practices

When it comes to testing a cabling installation, there are essentially three choices--verification, qualification and certification. Verification is great for troubleshooting as it will tell you if your cabling is connected correctly and can help you find breaks, connectors and splices. Qualification lets you know if your cable under test will support a specific application, making it great for small moves, adds and changes or determining if an existing cable plant can support an application (think 2.5/5GBASE-T testing over an installed base of Cat 6).

But only certification will tell you if the cable plant fully meets industry standards – it’s the only test that measures across predefined ranges and compares the results to TIA, ISO and IEEE specifications to determine if a link is compliant with a specific category or class of cable and able to support the application. Certification is also what most cable manufacturers require for a warranty.

Aside from the peace of mind that a manufacturer’s warranty provides, here are 7 more good reasons to certify – whether you’re the owner, the consultant or the installer.

1. Keep Bad Materials and Workmanship Out

Requiring certification puts the cabling contractor on notice: you won’t be accepting substandard components or work – so don’t even try. Contractors who cut corners may not bid when certification is required – and that’s a simple way to weed those firms out. Further, since certifying will show the performance details of the link including crosstalk and return loss, you’ll have a clear picture as to why a link might fail. Testers such as the DSX CableAnalyzer Series can isolate the exact cause of the failure, whether it’s the connectors, workmanship, or the cable itself. This allows the contractor to remedy those problems quickly, keeping your project on schedule.

2. Requirements Keep Getting Tighter

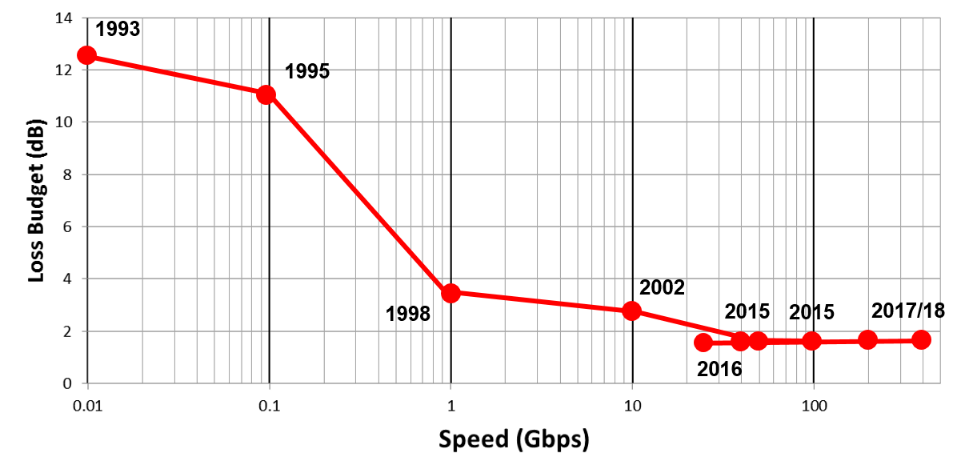

New technologies typically require more performance from media than the ones they replace. For example, in 1995, when we were running 100 Mb/s, fiber insertion loss budgets were at 11dB. Connector quality was unimportant, cleaning was seldom necessary and even testing was a luxury. But with the advent of Gigabit Ethernet in 1998, loss budgets dropped significantly, and today, some have loss limits of less than 2 dB. With these stringent insertion loss budgets, certification is a must to make sure your cabling plant can support the application it’s intended to support.

3. You Can’t Trust Link Lights!

Just because the little light on the port is on or blinking to indicate activity, doesn’t mean the network is performing as it should. Maybe it’s slow, maybe there are high bit errors or maybe it doesn’t work at all. Link lights won’t tell you that, but certification will.

4. You Don’t Have Time to Fix Someone Else’s Work

When you certify and have a clear picture of the cable plant performance you just installed, you’ve got the proof you need to avoid fixing someone else’s work. Anything else puts the sole responsibility upon you. Who’s got time for that? You’ve got a network to run.

5. Certification is Inexpensive

We’re not exactly sure where that myth that certification is expensive came from, but why would you install something as critical as the foundation behind all your communications, data transmission and transactions without spending a small fraction to ensure it works? Most installers using Fluke Network’s Versiv® family of certification testers tell us that certification is only about 5% of the total install costs. And don’t forget that if you have to go back and fix someone else’s work, the average cost-per-link is about $100 for a commercial installation.

6. Avoid the Blame Game

When several stakeholders – the installer, the owner’s network team and the manufacturer – all have the potential to impact performance, wouldn’t it be nice to have a certification report that shows the network performed at the time of installation? That makes it difficult for anyone to point the finger when performance issues arise down the road. And if your report says “Fluke Networks” on it, you’ve got even more peace of mind. That’s because over 30 manufacturers have endorsed the DSX CableAnalyzer (and most of them use it for their own field testing), so they won’t question your test results – so long as you keep it calibrated.

7. Be Ready for the Future

Last but certainly not least, certification of the cabling plant is the best way to make sure your installation is ready to support the next application coming down the pike. With detailed performance specifications and proof that the cable plant is compliant with a specific category or class of cable, you can rest assured that all applications intended to run over that cable media will be supported today and tomorrow.