Aber ich komme nicht ans Ende!

April 30, 2020 / General

There are often times when you have to test a fiber link, but you can’t access the far end. One of our customers, for example, was required to test fiber links to offshore wind platforms. Unfortunately, in order to set foot on a platform, the technician would need to complete three days of safety training. Three days training, lost time and all to test just a pair of fibers running to each tower.

In the current shutdown environment, there are more areas than ever you may not be allowed into - factories, data centers, or even offices. Our safety and wellbeing in these times is paramount. The good news is that you can still test thoroughly and accurately, using the techniques outlined in this article and detailed in our new Knowledge Base article: Testing Single mode fiber when you can’t access the remote end.

One Test Instrument can do it all

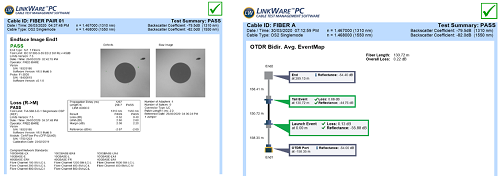

Using the Fluke Networks Versiv™ platform fitted with the CertiFiber® Pro OLTS modules and the OptiFiber® Pro OTDR module, you can achieve Tier 1 (Basic) testing and Tier 2 (Extended) testing without you even having to set foot on the remote site. By adding the FI-1000 FiberInspector® Pro USB camera you will also be able to provide connector end face images to prove that all the terminations were clean.

We are making use of the CertiFiber Pro OLTS Loopback test function to perform a loss/length measurement on a fiber pair, at the two required wavelengths, in less than 3 seconds. Loopback is a little-used feature of the CertiFiber Pro that allows one module to act as a single light source / power meter combination – perfect for this application.

Unfortunately, this approach does not tell us if one fiber of the pair is exceptionally good and the other fiber poor. We are seeing a combined result from the OLTS that could be masking this possibility. To get around this problem we use our OptiFiber Pro OTDR configured to perform a SmartLoop OTDR test.

The SmartLoop function of the OptiFiber Pro series of OTDRs allows the operator to measure both fibers from either end of the link without having to move the OTDR to the remote end or disturb the connected launch cable at the fiber under test connection. The OptiFiber Pro OTDR then processes the bi-directional measurements for each fiber and calculates the bi-directionally averaged result. A bi-directionally averaged result is the most accurate measurement of a fiber when using an OTDR and is a requirement of some standards.

Don’t forget your fiber hygiene! Dirt is one of the key issues that causes fiber testing to fail. Inspection and cleaning is the critical first step in all fiber optics testing; we have a Knowledge Base article on Inspection and cleaning: Cleaning Fiber Endfaces

One platform, Tier 1 loss test and Tier 2 OTDR trace plus End Face Inspection, all put together in one test report.

Before you get going

Organize help at the remote site! When it is time to test, you are going to need some assistance to plug in a loopback cord and a SmartLoop cord.

Before attempting to test, you need to ship to the remote site, well in advance, a Test Reference Cord (TRC) to be used as the loopback cord to loop around the fiber pair at the remote site and a SmartLoop cord to enable OTDR testing. Make sure all the cords’ connectors are clean before shipping the items! Send the appropriate QuickClean® cleaners with the cords so your remote location assistant can clean the fiber terminations, if necessary.

Getting the paperwork completed

The final step is getting the test report completed. Fluke Networks LinkWare® solutions will allow you to generate the required test reports for your client. LinkWare will allow you to combine your Inspection results, OLTS results and OTDR results into one comprehensive test report; in a format that is considered to be the industry de facto standard for test reports.

For the complete procedure, please refer to the Knowledge Base article.