Short-Reach Single-Mode Puts Reflectance on the Radar

August 6, 2019 / General, Standard and Certification, Industrial Networks, Best Practices

Most of us are well aware that insertion loss budgets have gotten tighter as we have moved from 10 to 40/100 Gig for multimode fiber applications. One would think that we can’t say the same for single-mode applications that have historically meant larger loss budgets – 6.3dB for 100 Gig over singlemode (100GBASE-LR4) versus just 1.9dB for 100 Gig over multimode (100GBASE-SR4). But that’s no longer the case with new short-reach single-mode applications.

And it’s not just insertion loss that matters with these applications; you now need to also be concerned with reflection.

Budget Awareness

With lower cost, low-power transceivers used in new short-reach single-mode applications such as 100GBASE-DR, 200GBASE-DR4 and 400GBASE-DR4 come reduced insertion loss allowances, bringing 100 Gig over short-reach single-mode (100GBASE-DR) down to just 3.0dB.

With these lower insertion loss limits, just like with multimode, multiple connections could mean trouble. When selecting single-mode connectivity, designers now need to pay attention to insertion loss and select low-loss components to stay within budget – a standard 0.75dB connector will no longer do. (If you do the math, it’s easy to see that four 0.75dB connectors and the loss of your cable will put you over budget in a 100GBASE-DR channel).

Not only do you need to be aware of the reduced insertion loss budget with these new short-reach single-mode applications, you also need to be aware that insertion loss is no longer your only concern. Reflectance that measures the amount of light reflected back to the transceiver is now a concern with short-reach single-mode applications, and for the first time, insertion loss limits will be dependent on it.

Reflections Matter

Before we delve into the fact that reflectance is now a concern in short-reach single-mode applications, let’s take a step back. You may recall in a previous blog where we covered return loss and reflectance. They are really one and the same as both measure light reflected back into the transceiver, but return loss is always a positive number and reflectance is always negative (See Cabling Chronicles Blog Are You Positive It’s Negative).

At a fiber connector, there is always a small air gap between the two fibers, and the difference in refractive index between the glass and the air causes light to be reflected back. While multimode transceivers are extremely tolerant of reflection, single-mode transceivers are not. In fact, with high power single-mode lasers, too much reflection can actually destroy the transceiver. APC connectors that have an 8-degree angled end face offer better reflectance (and return loss) because the angle reflects light back into the cladding rather than straight back toward the transceiver. (Yep. We wrote a blog on that too). All multi-fiber MPO single-mode connectors are APC because it’s impossible to achieve required reflectance on an MPO with a straight UPC end face.

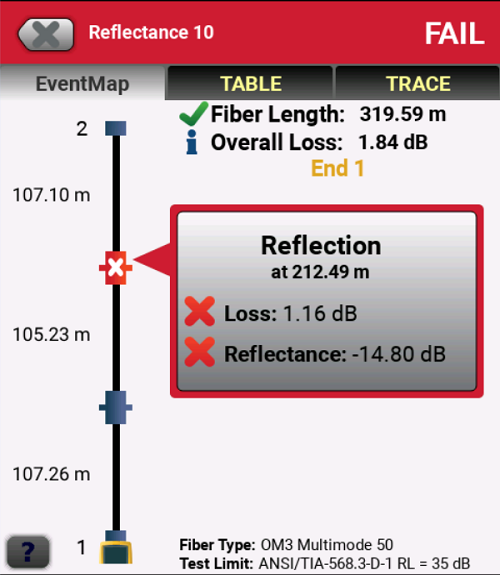

Within industry standard, TIA 568.3-D standard specifies connector return loss (positive) but it is not required in Tier 1 testing. However, when you look at the IEEE 802.3 Ethernet standards, they specify reflectance (negative). So, with new short-reach single-mode applications, it’s reflectance we care about. In addition, in Tier 2 testing, OTDRs report reflectance – not return loss.

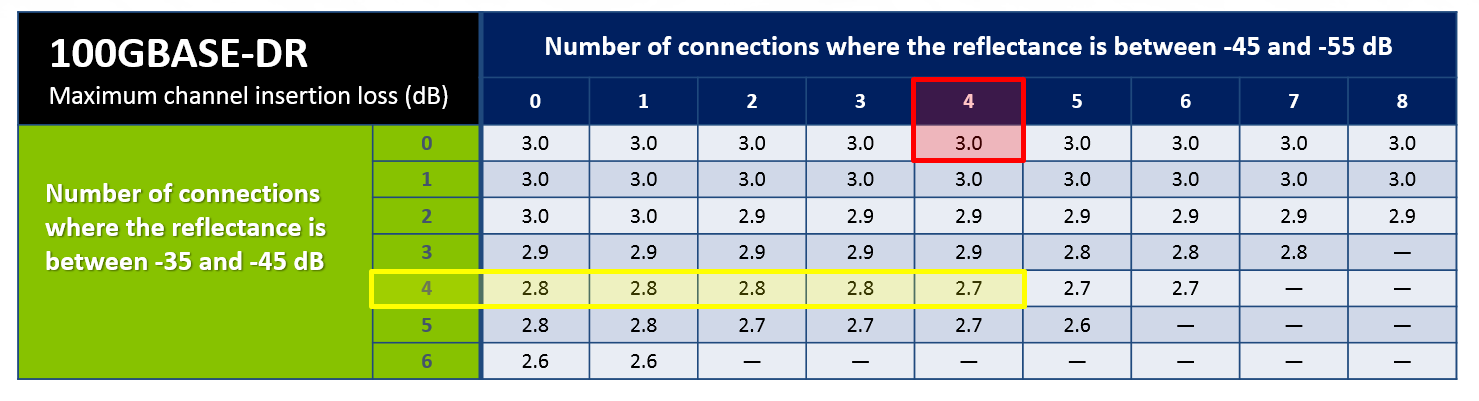

For new short-reach applications, IEEE actually specifies insertion loss limits based on the number and reflectance of connections in the channel, fueling the case for APC connectors. As shown below, in a 100GBASE-DR4 application with four connectors that have a reflectance between -45 and -55dB, the insertion loss is 3.0dB (highlighted in red in the table). But with four connectors that have a reflectance between -35 and -45dB, the insertion loss goes down to 2.7dB (highlighted in yellow in the table). This is a good time to remind you that values further away from zero are better for reflectance.

What Should You Design To?

With most single-mode LC and MPO connectors having a typically reflectance of about -55dB, it might seem that you could easily design your channel with an insertion loss of 3.0dB. Not so fast. Reflectance can change over time as jumpers are removed and inserted without cleaning, so just because they were -55dB on day one, does not mean they’ll be -55dB forever.

Dirt and debris can settle on connector end faces with normal day-to-day insertions and removals, and this can increase reflectance over time – especially in single-mode connectors where the fiber core is much smaller and it’s easier to block more light with a tiny dust particle than it is with multimode and a larger core. Even if connectors measure -55dB reflectance in Tier 2 OTDR testing, you’d be wise to build in some margin to take into consideration the potential for increased reflectance down the road. In the case of four connectors in a 100GBASE-DR application, that might mean designing to 2.7dB rather than 3dB.

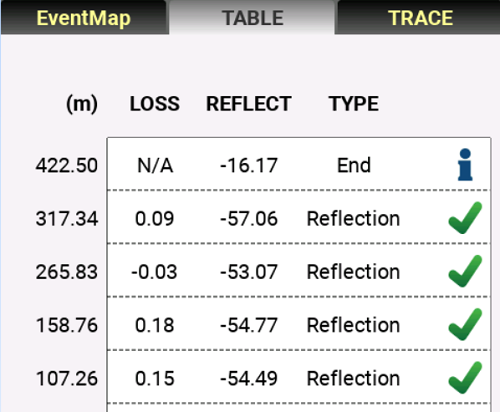

It’s important to know that even if your link passes Tier 1 (loss) testing with plenty of margin, too much reflectance can still render that link inoperable. That’s where an OTDR such as our OptiFiber Pro comes in handy – it can measure reflectance and even display the reflectance of every connection in a simple table (see image).

Don’t Forget the Golden Rule

Another key consideration for these new short-reach single-mode applications (or for any fiber application), is proper inspection. Just because the manufacturer tells you that the reflectance on a connector is -55dB, that doesn’t mean that it will have that performance out of the bag. That’s why it’s important to inspect, clean, and inspect every connector before you connect.

And since connectors can become dirty over time as jumpers are unplugged and plugged, inspecting and cleaning shouldn’t just be something that is done on day one – especially in short-reach single-mode applications where degraded reflectance performance can impact insertion loss and overall channel performance.

And if you’re inspecting APC connectors with a solution like the Fluke Networks FI-700 FiberInspector Pro or FI-500 FiberInspector Micro, don’t forget that you need to use the APC probe tip (purchased separately) to accommodate the 8-degree angle and ensure proper viewing.