What Ever Happened to the Mechanical Splice?

April 23, 2019 / General, 101 learning, Installation and testing, Upgrading and troubleshooting, Best Practices

When it comes to joining two or more optical fibers together, fusion splicing whereby cleaved fibers are aligned and fused by an electric arc provides the lowest loss and strongest, most reliable joint.

While mechanical splice connectors have come a long way and are an ideal field termination method for connectorizing fiber, we rarely hear much anymore about mechanical splicing as a means for joining fibers along a link – even though it eliminates the need for expensive fusion splicing equipment.

So what ever happened to the mechanical splice anyway?

Groovy But Not So Permanent

Rather than being permanently fused via an electric arc using a fusion splicer, a mechanical splice is where two fibers are simply held together in a way that aligns the fiber cores so that light can pass from one to another. As with fusion splicing, a good quality cleave that creates a flat fiber endface is critical to the process.

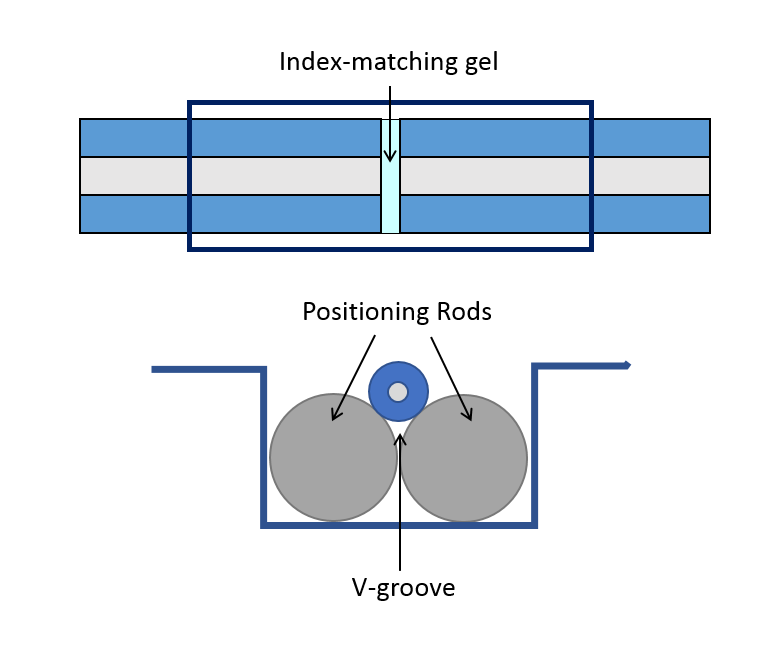

One of the most common methods for aligning fiber in a mechanical splice is the use of adhesive known as index-matching gel. In this scenario, two fibers are aligned and held together within a tube or housing of sorts and the index-matching gel creates the bond. The term “index-matching” refers to the fact that the gel is designed to match the refractive index of the fibers being joined to prevent reflection and optimize transmission. (Just in case you forgot what refractive index means, it’s the parameter that determines how much light is bent, or refracted, when entering a material.)

Another mechanical splice method is the V-groove. This involves the use of a substrate or positioning rods to form the V-groove that aligns the two fibers. In the substrate option, adhesive is used to secure the fiber to the grooved substrate. In a positioning rod V-groove, two adjacent rods form the groove and either a flat spring or a third positioning rod is then used to press the fiber into the groove.

So What’s the Problem?

While mechanical splicing has some advantages – it can be less expensive for small jobs due to fast deployment times and no fusion splicer required – it is primarily now used just for emergency repairs and temporary connections in multimode fiber links. The main reasons for this are reliability and performance.

In general, mechanical splices are not considered as reliable over time. Since a mechanical splice involves two fiber ends joined in a tube or V-groove, the fibers can be more easily pulled out of the splice. While index-matching gel has come a long way, some lower-quality gels can break down over time. And because the refractive index of some index-matching gels can vary with temperature, mechanical splices may not hold up to ambient temperature changes – you can guarantee that fiber splices in Antarctica are not relying on index-matching gel.

But perhaps the biggest reason why mechanical splices are not as popular as they used to be is performance. First of all, it’s not an ideal method for joining singlemode fibers due to the smaller fiber cores that are difficult to align. Secondly, the insertion loss for a mechanical splice can range from 0.2dB to as high as 0.75dB while a proper fusion splice can exhibit a loss of less than 0.1dB. Insertion loss is the primary performance parameter required to certify a fiber link, and with the latest high-speed fiber applications (like 40 and 100 Gig) having stringent loss requirements, mechanical splices could push an insertion loss budget beyond the limit.

If performance and reliability aren’t enough to convince you that fusion splicing is the way to go for today’s fiber links, there have been plenty of studies that demonstrate fusion splicing is ultimately the cheaper option for anyone that does splicing on a normal basis. Not only have fusion splicers come down in cost over the past decade, but by the time you’ve done a few hundred mechanical splices, you’ve likely spent more than if you had purchased the fusion splicer to begin with.

Regardless of your splice type, when it comes to troubleshooting them, the OTDR is your best friend. Fluke Networks’ OptiFiber® Pro can tell you the location and loss of your splices. But if your splice doesn’t properly align the fiber cores (more commonly a problem with mechanical splices versus fusion), the splice could result in negative loss in one direction and too much loss in the other. That’s why it’s important to do bidirectional testing that measures loss in both directions using the OptiFiber® Pro’s built-in “SmartLoop OTDR" Assistant that allows you to test in both directions from one end and then automatically averages the two measurements to provide the actual loss.