Is Your Fiber End Face Up to Scratch?

February 21, 2018 / General

While it seems we can never hammer home enough the need to properly clean and inspect fiber end-faces since contamination remains the number one cause of fiber link failures, have you ever thought about what exactly you are cleaning and inspecting?

Defects on a fiber end-face come in all types, shapes and sizes. They include scratches, cracks, and pits and contaminants like dirt, dust, oil and even salt. If you properly clean a fiber end-face  with lint-free wipes and a specialized solvent designed specifically for fiber cleaning, it’s possible to remove contaminants from the fiber end-face. But what about permanent surface defects like scratches, cracks and pits that can’t be removed via cleaning?

with lint-free wipes and a specialized solvent designed specifically for fiber cleaning, it’s possible to remove contaminants from the fiber end-face. But what about permanent surface defects like scratches, cracks and pits that can’t be removed via cleaning?

Pits typically appear as irregular shaped areas where glass has been removed due to either improper handling, poor manufacturing processes or hard debris on the fiber end-face present during mating. Cracks appear as jagged lines on the fiber end-face, and while they may resemble a scratch, they are much deeper. Pits and cracks usually mean the connector needs to be repolished or replaced. But scratches are little different. Defined as a having greater length than width, a scratch on a fiber end-face doesn’t necessarily mean it won’t pass inspection. But it doesn’t necessarily mean it will either. That’s because when it comes to scratches, it’s all about the size and location.

Size, Number and Region Matter

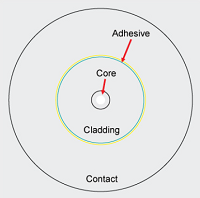

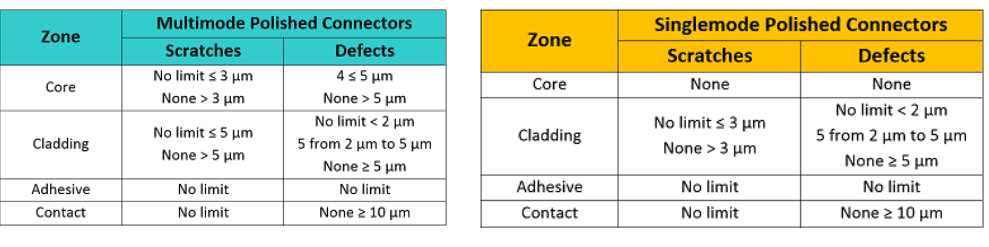

The IEC 61300-3-35 Basic Test and Measurement Procedures Standard for Fiber Optic Interconnecting Devices and Passive Components contains specific cleanliness grading criteria to assess pass or fail certification for inspection of a fiber end-face. The IEC 61300-3-35 certification criteria is based on the number and size of scratches and other defects found in each measurement region of the fiber end-face, including the core, cladding, adhesive layer and contact zones. Of course, the core of the fiber where the signal travels has the most stringent requirements.

And considering the difference in core size between singlemode and a multimode fiber, it makes sense that the criteria varies based on connector type and fiber size. So a scratch or defect that passes on a multimode fiber, might not pass muster on a singlemode. For example, as shown in the tables, a multimode fiber can have a 2 μm scratch in the core and still pass inspection, while a singlemode fiber would not.

Not Fit for Human Eyes

he sizes we are talking about for scratches and defects cannot be seen with the human eye – consider that a human hair has an average cross-section of around 50 μm and the human eye cannot see anything smaller than 40 μm. That’s why you need a microscope to inspect fiber end-faces.

But to really inspect an end-face per the IEC 61300-3-35 criteria, you would also need to measure and count the scratches and defects – another task that is virtually impossible with the human eye.

Thankfully Fluke Networks’ FI-7000 FiberInspector Pro does the work for you. Through its algorithmic processes that automatically and quickly inspect, grade and certify fiber end-faces based on the IEC 61300-3-35 criteria, FiberInspector Pro knows exactly how many, how big and where scratches and defects are located on the fiber end-face. So you can rest assured that your connectors are up to scratch, helping ensure optimum fiber network performance for your customers.