DATASHEET

Industrial Ethernet CableAnalyzer™ Kit (DSX2-5-IE-K1)

Download PDF

Cabling in Industrial Environments

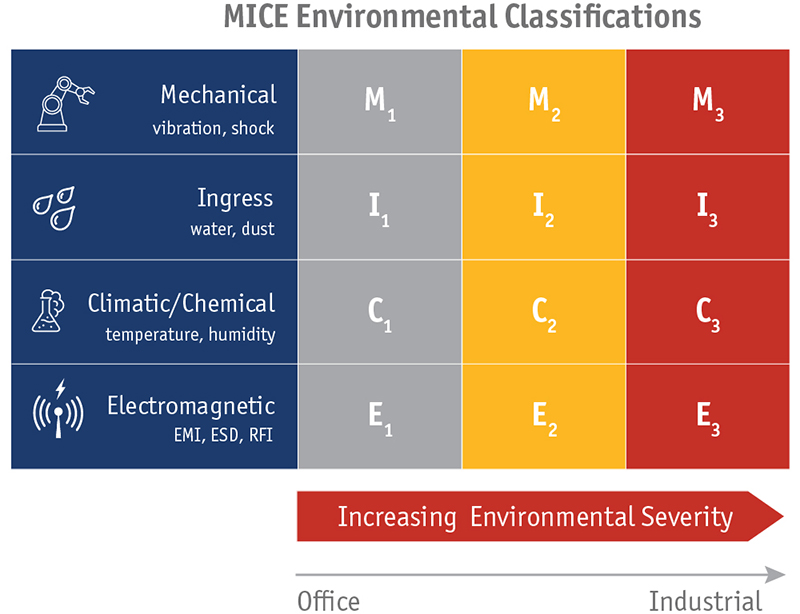

ISO/IEC 11801-3 and ANSI/TIA-1005-A are telecommunications infrastructure standards for Industrial Premises. These standards were created to reduce problems in harsh industrial environments. The standards use the term MICE to explain 4 important factors impacting industrial networks.

Mechanical; vibration, physical shock, rough handling

Ingress; chemicals and water, especially in wash-down environments

Climatic; temperature extremes found in industrial processes

Electromagnetic; noise from motors, VFDs, welding processes, etc.

Standards have 3 MICE levels to help identify the severity of the environment

Level 1: Control and data rooms. This is usually an office environment

Level 2: Factory floor. This is usually between the manufacturing equipment and control rooms

Level 3: Manufacturing and automation areas

On This Page

- Overview

- Find Cables Susceptible to Mechanical Vibration (M), Moisture Ingress (I) & Climatic/Temperature (C) Issues

- Find Cables Susceptible to Electromagnetic Interference (EMI) with TCL and ELTCTL Tests

- Find 4 Pair Cables with Bad Shield with the Shield Integrity Test

- ProjX™ Management System Manages Complex Jobs with Ease

- Taptive User Interface Simplifies Set Up, Eliminates Errors and Speeds Troubleshooting

- Troubleshoot Like An Expert

- Performs with Unsurpassed Speed

- DSX CableAnalyzer Series Specifications

- Ordering Information

Overview

Industrial environments are much harsher and more time sensitive than traditional IT environments. Ethernet packets can be corrupted (CRC, FCS errors) causing packet re-sends which increases latency which can disrupt communications resulting in production delays.

Cables that appear good and pass basic continuity and speed tests can be susceptible to vibration, moisture and contamination, temperature changes, and electromagnetic noise (factors referred to as MICE — see above) in a manner that causes ethernet packets to be intermittently corrupted.

The DSX Industrial Ethernet CableAnalyzer™ (DSX2-5-IE-K1) is based on the Fluke Networks DSX-5000 and supports testing copper Industrial Ethernet networks and has optional modules to support fiber optics.

- Validate that cables conform to international standards.

- Faster Startup: Ensure cable performance at machine builder, commissioning and after making changes.

- Prevent downtime: Find marginal cables susceptible to vibration, moisture, noise and temperature.

- Speed troubleshooting: Avoid wasting time installing bypass cables.

- Identify the exact type and location of cable failure—or prove it’s good.

- Pass/Fail indication in 10 seconds

- Supports cabling for EtherNet/IP™, PROFINET™, ModBus TCP™ and other industrial networks

- Supports RJ45 and M12 connectors

- Documentation of test results for commissioning

Find Cables Susceptible to Mechanical Vibration (M), Moisture Ingress (I) & Climatic/Temperature (C) Issues

Continuity testers are designed to find open and shorts, but it is possible for a cable to pass a continuity test and have intermittently higher resistance (or even open circuit) on one or more of the wires in the cable that appear with vibration, moisture or temperature changes. This can cause intermittent packet loss adding excessive latency to time sensitive networks.

The DSX CableAnalyzer features a unique resistance unbalance test that measures resistance on all 4 or 8 wires in the cable. One wire with higher resistance than the other wires is likely to become intermittent.

All 4 pairs have nearly equal resistance

Excessive resistance which could cause an intermittent connection

Find Cables Susceptible to Electromagnetic Interference (EMI) with TCL and ELTCTL Tests

EMI corrupts data packets which is why Transverse Conversion Loss (TCL) and Equal Level Transverse Conversion Transfer Loss (ELTCTL) requirements are included in the standards for UTP systems to protect against Electrostatic Discharge (by direct contact and through air) — up to 8kV, radio frequency interference, surges (line to earth) — up to 1kV, and magnetic fields (motors and relays).

Cables (including pre-terminated cables) can pick up EMI (noise) from other data cables, power cables, motors, motor drives, and other sources. This is caused by a lack of balance in the cable due to untwisted wires, excessively tight cable ties, sharp radiuses, excessive bends and other factors.

Cable susceptible to EMI

Cable that may contain water

Find 4 Pair Cables with Bad Shield with the Shield Integrity Test

The CableAnalyzer can distinguish between an equipment ground path and the actual shield (or screen) used on some 4 pair cables. The Wire Map display provides a Pass/Fail indication and the distance to the fault.

Wire map indicating a bad shield

ProjX™ Management System Manages Complex Jobs with Ease

Manage up to 12,000 test results with full graphics

Managing the testing of multiple jobs with multiple teams, testers, and requirements is time consuming and a source of errors. Increasingly larger jobs make project organization more important than ever. The ProjX management system on the DSX CableAnalyzer Series provides individual project files for all job specific details to be saved under a simple name, eliminating the need to re-enter job specific details after starting a project. This minimizes set-up errors or lost files when switching from one job to another or utilizing multiple testers on a single job. In addition, it provides test results by cable ID, merges any changes without duplicates and defaults to the last copper or fiber module installed. ProjX management system provides real time status to completion on each job with a 0-100% scale and gives the operator the option to isolate any test requiring a second look and helps to assure nothing is overlooked. The "Fix Later" selection creates a punch list or automatic to do list for correcting any workmanship issues. ProjX enables project managers and crew leaders to be truly efficient.

Project Menu screen shows percent complete per job

Project specific screen shows up to the minute project details

Taptive User Interface Simplifies Set Up, Eliminates Errors and Speeds Troubleshooting

Capacitive touchscreen allows quick tester setup and supports all standards

Taptive user interface is easy enough for even the newest technician to perform tests across multiple media types and testing requirements. The capacitive Taptive user interface makes all jobs easily accessible from the menu screen. Touch the job you’re working on and the large display confirms the test that needs to be performed, animated instructions simplify setting the configuration making correct testing assured.

Simple Setup

Quickly enter Cable Ids with the capacitive touchscreen

Troubleshoot Like An Expert

Graphically displays the source of failures including crosstalk and distance to shield faults for faster troubleshooting

The DSX reduces the time required to fix cabling faults with dedicated diagnostics, a simple 1 button test runs all tests and saves all data. The graphical results screen allows you to look down the cable to see exactly where any cross talk, return loss or shield faults are located on any given link. This common view is easily interpreted by novice and expert users alike to isolate and act on any failed results quickly and is stored with the test result for remote analysis.

High Definition Domain Cross talk (HTDTX) shows the far end connection is clearly the issue

Features simple diagnostic based on decades of Fluke Networks troubleshooting experience

Performs with Unsurpassed Speed

Document cable performance with pass/fail results in as little as 8 seconds.

No tester offers so much speed for so many tests. Complete copper certification to Cat 6A in 8 seconds or certify two fibers at two wavelengths in just 3 seconds. Compete copper cable testing to international standards in 8 seconds per link. Test fiber optic links (requires optional fiber optic modules) in under 3 seconds per link.

Passing test result

Return loss graph

Pinch and zoom for more detail

DSX CableAnalyzer Series Specifications

| Cable Types | |

|---|---|

|

Shielded and unshielded pair LAN cabling |

TIA Cat 3, 4, 5, 5e, 6, 6A, 100 Ω ISO/IEC Class C, D, E, EA, F, FA and I/II: 100 Ω and 120 Ω |

| Adapters and Test Standards | |

|---|---|

| Adapters | RJ45 channel, M12-D (2 pair) and M12-X (4 pair) |

| TIA | Cat 3, 4, 5, 5e, 6, 6A per TIA 568 Series |

| ISO/IEC | Class C, D, E, EA, F, FA, certification per ISO/IEC 11801 Series |

| General Specifications | |

|---|---|

| Supported test parameters (The selected test standard determines the test parameters and the frequency range of the tests) | Wire Map, Length, Propagation Delay, Delay Skew, DC Loop Resistance, Pair-to-Pair Resistance Unbalance, Pair Resistance Unbalance, Insertion Loss (Attenuation), Return Loss (RL), Common Mode Return loss (CMRL), Near End Crosstalk (NEXT), Far End Crosstalk (FEXT), Attenuation-to-crosstalk Ratio (ACR-N), ACR-F (ELFEXT), Power Sum ACR-F (ELFEXT), Power Sum NEXT, Power Sum ACR-N, Power Sum Alien NEXT (PS ANEXT), Power Sum Alien Attenuation NEXT Ratio Far End (PS AACR-F), Common Mode to Differential Mode NEXT (CDNEXT),Transverse Conversion Loss (TCL), Equal Level Transverse Conversion Transfer Loss (ELTCTL) |

| Input protection | Protected against continuous telco voltages and 100 mA over-current. Occasional ISDN over-voltages will not cause damage |

| Display | 5.7 in LCD display with a projected capacitance touchscreen |

| Case | High impact plastic with shock absorbing overmold |

| Dimensions | Main Versiv unit with DSX module and battery installed: 2.625 in x 5.25 in x 11.0 in (6.67 cm x 13.33 cm x 27.94 cm) |

| Weight | Main Versiv unit with DSX module and battery installed: 3 lbs, 5oz (1.28 kg) |

| Main unit and remote | Lithium ion battery pack, 7.2 V |

| Typical battery life | 8 hours |

| Charge time* | Tester off: 4 hours to charge from 10 % capacity to 90 % capacity |

| Languages supported | English, French, German, Italian, Japanese, Portuguese, Spanish, Chinese, Korean, Russian, Trad Chinese, Czech, Polish, Swedish, Hungarian |

| Calibration | Service center calibration period is 1 year |

| Integrated Wi-Fi | Meets IEEE 802.11 a/b/g/n; dual band (2.4 GHz and 5 GHz) |

| Software Support | LinkWare Live cloud-based service lets you manage certification jobs. LinkWare PC Management Software allows you to easily generate certification reports and upgrade software in your tester. |

| Environmental Specifications | |

|---|---|

| Operating Temperature | 32° F to 113° F (0° C to 45° C) |

| Storage Temperature | -22° F to +140° F (-30° C to +60° C) |

| Operating relative humidity (% RH without condensation) | 0% to 90%, 32° F to 95° F (0° C to 35° C) |

| 0% to 70%, 95° F to 113° F (35° C to 45 °C) | |

| Vibration | Random, 2 g, 5 Hz-500 Hz |

| Shock | 1 m drop test with and without module and adapter |

| Safety | CSA 22.2 No. 61010, IEC 61010-1 3rd Edition |

| Operating altitude |

13,123 ft (4,000 m) 10,500 ft (3,200 m) with ac adapter |

| EMC | EN 61326-1 |

Ordering Information

| DSX Industrial Ethernet Models and Accessories | |

|---|---|

| Model | Description |

| DSX2-5-IE-K1 | DSX Industrial Ethernet Kit (includes tester, RJ45, M12-X and M12-D cable adapters) |

| GLD-DSX2-5-IE-K1 | 1 YR Gold Support Package for DSX2-5-IE-K1 |

| GLD3-DSX2-5-IE-K1 | 3 YR Gold Support Package for DSX2-5-IE-K1 |

| DSX-OFP-Q-ADD | DSX-5000 with Quad OTDR Add-on Kit |

| DSX-PLA004S | DSX Cat 6A/Class EA Permanent Link Adapter Set |

| DSX-PLA004-RKIT | Cat 6A/Class EA PLA Adapter – Plug Replacement Kit |

| DSX-CHA004S | DSXcCat 6A/Class EA Channel Adapter Set |

| DSX-COAX | DSX Coax Adapter Set |

| DSX-CHA021S | DSX M12 4-Position Adapter Set |

| DSX-CHA-M12-X-S | DSX M12X 8-Position Adapter Set |

| DSX-PC5ES | DSX Patch Cord Test Adapter Set for Cat 5e patch cords |

| DSX-PC6S | DSX Patch Cord Test Adapter Set for Cat 6 patch cords |

| DSX-PC6AS | DSX Patch Cord Test Adapter Set for Cat 6A patch cords |

| DSX-PC5E | Single Patch Cord Adapter for Testing Cat 5e MPTL |

| DSX-PC6 | Single Patch Cord Adapter for Testing Cat 6 MPTL |

| DSX-PC6A | Single Patch Cord Adapter for Testing Cat 6A MPTL |

| Versiv-TSET | VERSIV Headphones |

| VERSIV-BATTERY | VERSIV Battery |

| VERSIV-ACUN | VERSIV Charger |

| VERSIV-STRP | VERSIV Hand Strap |

| VERSIV-STND | VERSIV Demo Stand |